Coil Winding Nozzle

The nozzle is an important component for the wire outgoing section of an automatic winding machine, as they guide the wire during the winding process and ensure the final product is a neat and well-organized coil.

Durability

Because the coil winding nozzle will come into continuous contact with the wire, the material hardness and surface smoothness requirements are high. If the material selection and production process of the coil winding nozzle do not perfectly meet industry standards, the service life is directly influenced.

We use ruby, tungsten carbide and alloy steel to produce our coil winding nozzle. The wire inlet and outlet are treated by mirror polishing, thus reducing the coil winding nozzle’s abrasion to an absolute minimum.

Using the stainless steel nozzle with a ruby tip as an example, the hardness of the wire inlet and outlet reaches 2200 vickers. The smoothness of the inner hole is Ra 0.025, thus ensuring the nozzle has an extremely high wear resistance and will not break.

Optional type

Qinhe offers different coil winding nozzles for different industries. For the winding of transformers, inductors, voice coils and other products, customers can directly choose a stainless steel nozzle with a ruby tip or a tungsten carbide nozzle. We offer a variety of types to meet all customer requirements.

-

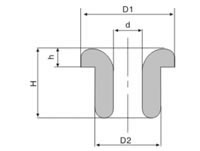

- Stainless Steel Nozzle with Ruby Tip The stainless steel nozzle with a ruby tip is the key wire guiding parts that are suitable for high speed winding of fine coils and ultra-thin enameled wire, as well as other conditions with strict requirements. During operation, the wire passes through the nozzle, and a winding process is carried out under nozzle guidance.

-

- Tungsten Carbide NozzleThe tungsten carbide nozzle is used primarily on the fully automatic winding machine for high speed winding of fine coils, and ultra-thin enameled wire grinding. It is often used for electronic appliance production processes, such as that for transformers, inductors, and voice coils.

Rotor and stator production in the motor industry features different coil winding nozzle requirements, due to the variable winding machine types. Because of this, the coil winding nozzle used for motor production is not available in standard types, and has a higher machining difficulty than normal coil winding nozzles.

We offer customization services for coil winding nozzles used in motor production. Simply give us your specific requirements, and we will carry out customized service.

-

- Motor Winding Nozzle The motor winding nozzle guides wire during the winding process of the motor stator and rotor in order to ensure a neat, well-organized coil winding. The nozzle is often used in electrical machinery such as fans, micro-motors and motors.

Hangzhou Qianhe Pricision Machinery Co.,Ltd.

Add.: No.16 Kangzhong Road, Kangqiao Industrial Park, Gongshu District, Hangzhou City, Zhejiang Province, China

Contact number:

+86-571-86179918