- Home

- Products

- Coil Winding Tensioning Device and Tensioners

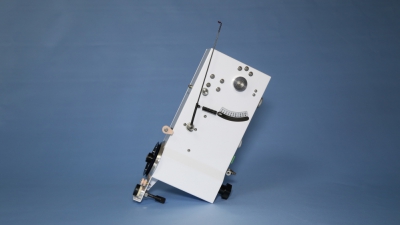

- Coil Winding Tensioning Device, ST600 ST800 ST2000 Tensioner

Coil Winding Tensioning Device, ST600 ST800 ST2000 Tensioner

Application

The coil winding ST600 ST800 ST2000 tensioner can precisely control the tensile force of various wires such as enameled wire, nylon wire and metal wire during the winding process. The most common application is for automatic winding machines for the production of motors and coils. It can also be used in textile machinery.

Because of the DC servo motor serving as the actuator for active wire feeding, this tensioner features quick response and high precision. The max wire feeding speed is up to 20m/s. So this tensioner is especially suited for the coil and motor production industry which requires high performance winding processing.

Qianhe can also provide coil winding ST600 ST800 ST2000 tensioner with display function so that it can show the tension value in real time, making it convenient for operators to monitor.

Features

(1) Constant tensile force

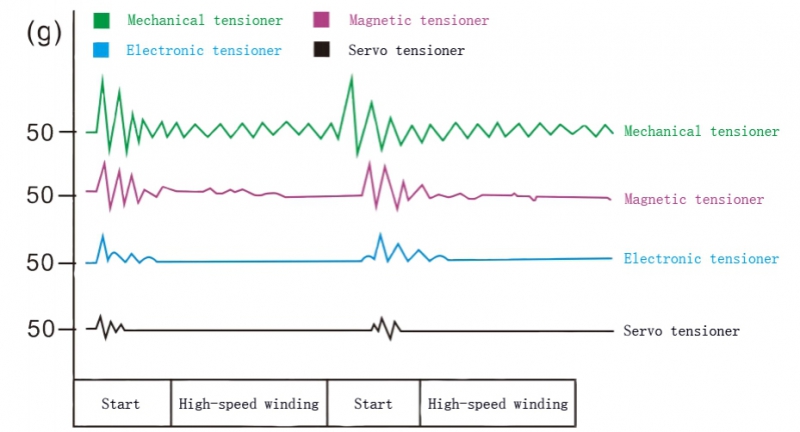

Compared with traditional mechanical tensioners and electrical tensioners, the servo tensioner features constant tensile force with the following features. It can ensure constant tension of the wire no matter how the winding speed changes. This means that:

1. The final coil will be uniformly and neatly arranged. And the size of the coil is reasonable.

2. It can ensure uniform resistance value of the coil.

3. It can avoid deformation of the plastic frame.

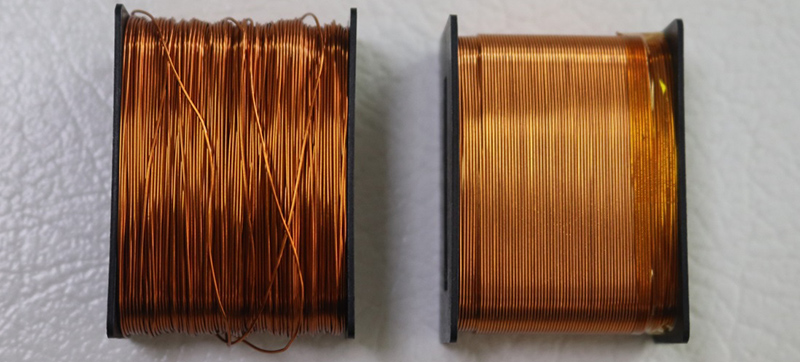

Left: by mechanical tensioners Right: by servo tensioners

Left: by mechanical tensioners Right: by servo tensioners

(2) Accurate measuring

This kind of servo tensioner has a built-in tension sensor which can conduct real time and automatic calculation of the torque of the servo motor. Use the complementation of two values to achieve accurate tensile force.

Meanwhile, the specific value of the tension can be displayed on the LED screen so that the operators can monitor the tension directly and conveniently, thus reducing reject ratio of the product and improve production efficiency.

(3) Quick response

The tensioner works along with the winding machine. While the advantage of the servo tensioner is that it can react rapidly during the start, speed raising or speed reduction of the winding machine to ensure constant tension.

(4) Fast wire feeding speed

The max wire feeding speed of the servo tensioner can be up to 20m/s. The speed raising from 0 to max speed can be accomplished within 0.2s. So it can perfectly suit the fully automatic winding machine with high requirements. Thus it can realize higher production efficiency for users.

(5) Two stage tension control

When your manufacturing process has the demands of going through the slot or wound feet, the tensioner cannot meet the production requirements if it can only provide one-stage tensile force.

This type of product has higher universality so that the operators can pre-set two stage tension of different values via programming. Then the tensioner can automatically provide two-stage tensile force under program control of the winding machine.

The control of two stage tension requires connection to an air source.

(6) DC servo motor

The actuator of the servo tensioner is a DC servo motor. Compared with the traditional stepping motors and hysteresis motors, it has lower noise.

Besides, even the winding machine is under high speed operation, the servo motor can still provide large torque so the servo tensioner features big range of tension and wide application.

Parameters

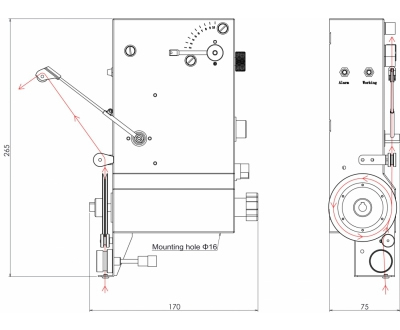

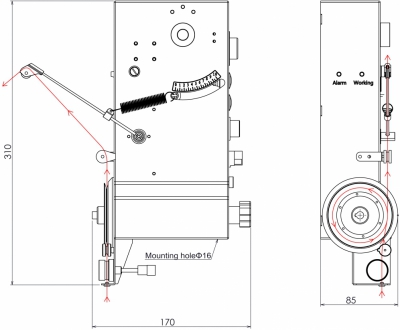

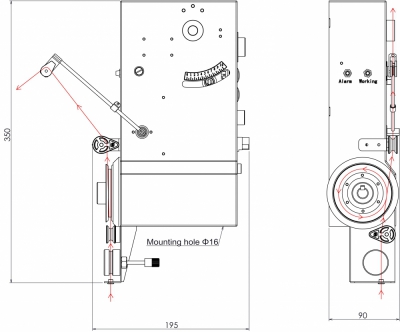

(1) Coil winding ST600 ST800 ST2000 tensioner| Product type | Max linear speed(m/s) | Tension range(gf) | Wire diameter range (mm) | Tension control stage | Supply voltage (V) | Power (W) | Connected air pressure (kg/cm2) | Installation pore diameter (mm) | Weight (kg) | Outline dimension (mm) | Optional tension rod | |

| ST600D-18 | 18 | 3-600 | 0.02-0.3 | Single stage tension control | DC36 | 100 | / | Ф16 | 2 | 265*170*75 | TR-25#-200 TR-26#-120 TR-27#-150 | |

| ST800-18 | 18 | 3-800 | 0.02-0.4 | Two-stage tension control | 5 | 2.5 | 310*170*85 | |||||

| ST2000-9 | 9 | 300-2000 | 0.2-0.8 | Two-stage tension control | 200 | 3.7 | 350*195*90 | TR-28#-150 |

This new product is designed and improved on the base of the existing servo tensioners, combining the tension measurement and control device and tensioner together. It can show the value of the tension in real time during running, so that the operators can learn the working condition of the equipment easily.

| Product type | Tension range (gf) | Wire diameter range (mm) | Installation pore diameter(mm) | Tension bar head structure | Optional spring model | Optional tension rod model | |

| SF50-Ⅰ/Ⅱ | 3~50 | 0.02~0.08 | Φ0.8-Φ2-150 | Ceramic Eylet /Ruby /Wire Roller(S) | T1、T2、T3 | SF-1# | |

| SF100-Ⅰ/Ⅱ | 25~100 | 0.05~0.12 | Φ1.5-Φ2-200 | Ruby /Wire Roller(S) | T3、T4、T5 | SF-2# | |

| SF200-Ⅰ/Ⅱ | 50~200 | 0.08~0.17 | Φ1.5-Φ4-200 | Ruby /Ceramic Pulley(005) /Wire Roller(M) | T4、T5、T6 | SF-3# | |

| SF400-Ⅰ/Ⅱ | 100~400 | 0.12~0.25 | Φ2-Φ4-150 | Ruby /Ceramic Pulley(005) /Wire Roller(L) | T5、T6、T8 | SF-4# | |

| SF800-Ⅰ/Ⅱ | 300~800 | 0.21~0.37 | Φ2-Φ4-120 | Ceramic Pulley(S) /Wire Roller(L) | T8、T9 | SF-5# | |

| SF2000-Ⅱ | 500~2000 | 0.3~0.8 | Φ4.0*120 | Ceramic Pulley(M) | TDM-B/C/D | TR-28# |

Hangzhou Qianhe Pricision Machinery Co.,Ltd.

Add.: No.16 Kangzhong Road, Kangqiao Industrial Park, Gongshu District, Hangzhou City, Zhejiang Province, China

Contact number:

+86-571-86179918